High-efficiency laser cleaning technology series

Introduction to high-efficiency series laser cleaning

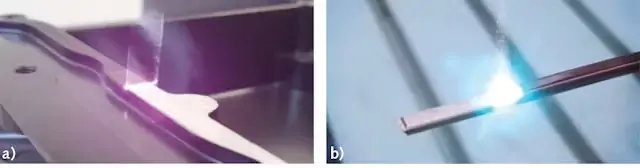

Laser cleaning technology is a high-performance surface cleaning method that converts direct current (DC) generated by solar panels into alternating current (AC) that can be used in homes and businesses. The core function of laser cleaning technology is to use high-energy laser beams to remove dirt, coatings or oxides from the target surface, ensuring cleanliness while maintaining surface safety and efficient output.

Application scope of laser cleaning high-efficiency series:

Metal surface cleaning: including the removal of oxides, oil stains, etc. from the surfaces of metal parts, mechanical equipment, etc.

Automotive industry: automotive surface coating removal, body cleaning, etc.

Electronics industry: PCB board cleaning, post-soldering cleaning, etc.

Art restoration: surface cleaning and restoration of ancient cultural relics and artworks.

Why Choose Megawatt Solar Inverter

Personalized parameters

We provide personalized equipment parameter customization services. According to the specific needs and application scenarios of customers, we adjust the working parameters of the equipment, including laser power, cleaning speed, cleaning range, etc., to ensure that the equipment can meet customer needs to the greatest extent.

Function customization

In addition to equipment parameters, we can also customize functional modules according to customers’ special needs. For example, according to the cleaning needs of different industries, specific cleaning modes, cleaning depth, degree of automation and other functions can be customized to ensure that the equipment can achieve the best cleaning effect.

Appearance customization

We also provide equipment appearance customization services. Customers can customize the appearance design, color matching, etc. of the equipment according to their own brand image and market needs, so that the equipment is more in line with the customer’s corporate image and market positioning.

Professional technical support

During the customized service process, we have a professional technical team to provide customers with full technical support and guidance. Whether it is adjustment of equipment parameters, customization of functions or appearance design, we will provide customers with professional suggestions and solutions.

Quality Assurance

We always take customer satisfaction as our primary goal. All customized equipment will undergo strict quality control and testing to ensure that the equipment performance is stable and reliable and meets customer expectations.

Delivery and after-sales service

We will ensure that customized equipment is delivered on time and provide comprehensive after-sales services, including equipment installation and commissioning, operational training, technical support, etc., to ensure that customers can use customized laser cleaning equipment smoothly.

How Does a Power Inverter Work?

Preparation

Set parameters

Perform cleaning

Check results

What are the uses of different inverters?

Manufacturing applications

Overview: Laser cleaning technology is widely used in the manufacturing industry to clean the surfaces of various materials, such as metals, plastics, ceramics, etc. It can effectively remove oil stains, coatings, oxides and other dirt, improving production efficiency and product quality during the manufacturing process.

Click me!

Automotive industry applications

Description: In the automobile manufacturing and maintenance process, laser cleaning technology can be used to clean vehicle body surfaces, engine parts, interior trim and other components. It can effectively remove dirt and coatings on the car body paint, keep the car’s appearance clean and bright, and enhance the overall texture and value of the car.

Click me!

Art recovery applications

Description: Laser cleaning technology is widely used in the field of art restoration and can be used to clean the surfaces of ancient sculptures, paintings, buildings and other cultural relics and artworks. It can easily remove dirt, oxides and paint residues attached to the surface of artworks, restore the original luster and color of artworks, and protect the integrity and value of cultural relics.

Click me!Jastar – Your partner for laser cleaning solutions

Jastar has excellent R&D capabilities in cleaning solution technology. We provide one of the leading laser cleaning solutions with enhanced intelligent monitoring functions. Globally, our products are known for their superior quality and reliability, earning us a strong market reputation. Choosing Jastar for your laser cleaning needs means increasing the efficiency and quality of your laser cleaning.

Blog about laser cleaning machines

Frequently Asked Questions

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.